1050 tiwb alwminiwm torchog

Manylebau

Manyleb Nodweddiadol o Diwb Alwminiwm

| aloi Nac ydw. | Tymher | Tiwb Syth | LWC | ||

| OD(mm) | WT(mm) | OD(mm) | WT | ||

| 1060(L2) | R(H112) | 6 ~ 30 | 0.6~3 | 4~22 | 0.2~2 |

| M(O) | 6 ~ 30 | 0.6~3 | 4~22 | 0.2~2 | |

| H 14 | 6 ~ 30 | 0.6~3 | 4~22 | 0.2~2 | |

| 3A21 3003 3103 (LF21) | M(O) | 6 ~ 30 | 0.6~3 | 4~22 | 0.2~2 |

| H12 | 6 ~ 30 | 0.6~3 | 4~22 | 0.2~2 | |

| H14 | 6 ~ 30 | 0.6~3 | 4~22 | 0.2~2 | |

| H18 | 6 ~ 30 | 0.6~3 | 4~22 | 0.2~2 | |

| 6063 (LD31) | M(O) | 6 ~ 30 | 0.6~3 | 4~22 | 0.5~2 |

| T4 | 6 ~ 30 | 0.6~3 | 4~22 | 0.5~2 | |

| T6 | 6 ~ 30 | 0.6~3 | 4~22 | 0.5~2 | |

Manyleb Tiwb Alwminiwm Groove Mewnol (gellir addasu maint)

| Manyleb(mm) | Trwch wal (mm) | Uchder rhigol (mm) | Ongl Helical(°) |

| 7 | 0.4-0.5 | 0.05-0.18 | 18 |

| 7.94 | 0.4-0.5 | 0.05-0.18 | 18 |

| 9.52 | 0.45-0.55 | 0.05-0.18 | 18 |

Priodweddau Mecanyddol Tiwb Groove Alwminiwm Mewnol

| Deunydd | Tynnol | Cyfradd Elongation | Cyfradd Ehangu |

| 3003 | 130MPA | 35 | 40 |

Manyleb Coil Pecyn

| OD | 6.35 | 7.94 | 9.52 | 12.7 | 15.88 | 19.05 |

| Trwch wal | 0.7-1.0 | 0.8-1,2 | 0.8-1.2 | 1-1.5 | 1-1.5 | 1-1.5 |

gwarant maint

1) ymddangosiad wyneb: wyneb glân fflat dim cyfan, crafu, olew yn fudr neu ocsideiddio.

2) flaen y gad: ymyl torri daclus dim burrs.

3) Nod ansawdd: cyfradd cymwysedig archwilio cynnyrch frist yw 98% boddhad cwsmeriaid o 95%. Deunydd: A1050, A1060, A1070, A3003, ac ati

| A1050 Cyfansoddiad Cemegol Alwminiwm | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Eraill |

| 99.5 ~ 100 | 0~0.25 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.40 | 0~0.03 |

| A1060 Cyfansoddiad Cemegol Alwminiwm | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Eraill |

| 99.6-100 | 0~0.25 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.03 | 0~0.03 | / | 0~0.35 | |

| A1070 Cyfansoddiad Cemegol Alwminiwm | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Eraill |

| 99.7 ~ 100 | 0~0.2 | 0~0.04 | 0~0.03 | 0~0.04 | 0~0.03 | 0~0.03 | 0~0.05 | 0~0.25 | |

| A3003 Cyfansoddiad Cemegol Alwminiwm | |||||||

| Al | Si | Cu | Zn | Mn | Fe | Eraill Sengl | |

| eraill | 0~0.6 | 0.05 ~ 0.20 | 0~0.1 | 1.0 ~ 1.5 | 0~0.70 | 0~0.05 | |

| aloi | Tymher | Manyleb | |||

| Trwch(mm) | Diamedr(mm) | Cryfder tynnol | Caledwch | ||

| 7075 7005 (tiwb) | T5, T6, T9 | >0.5 | 5.0-80 | >310 Mpa | >140 |

| 6061 6063 (proffil) | T5, T6 | >1.6 | 10-180 | >572 Mpa | HB90-110 |

| Hyd: < 6Metr | |||||

| TYMHOR | Trwch (mm) | CRYFDER TENSILE | ELONGATION % | Safonol |

| T5 | 0.4-5 | 60-100 | ≥ 20 | GB/T3190-1996 |

| T6 | 0.5-6 | 70-120 | ≥ 4 | |

| T9 | 0.5-6 | 85-120 | ≥ 2 |

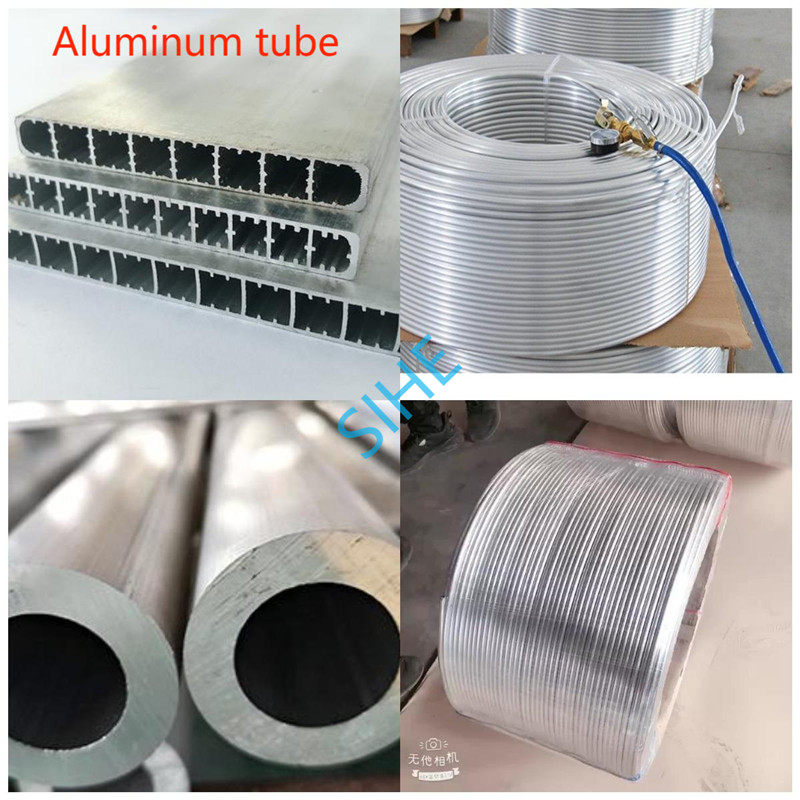

Cynnyrch alwminiwm

Ysgrifennwch eich neges yma a'i hanfon atom